Strike Zone Super Pit

|

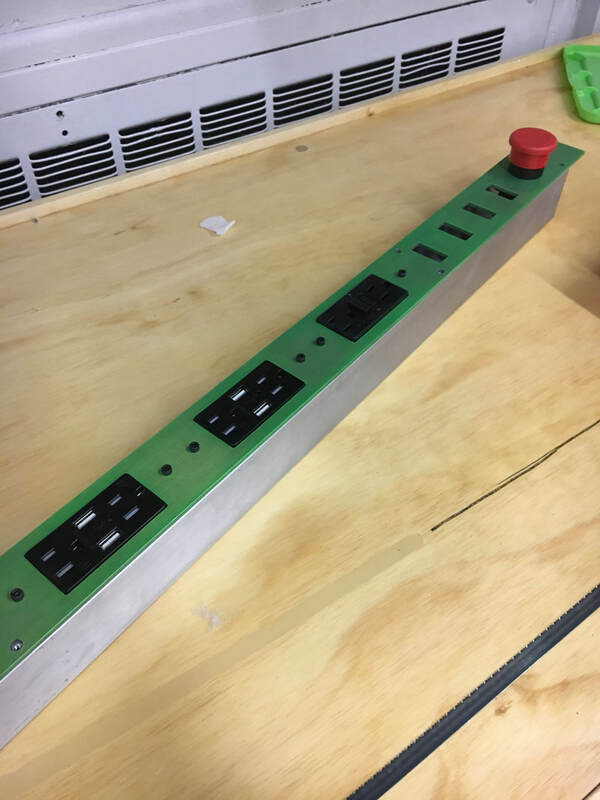

In the off-season of 2017, the team decided to do some pit upgrades. While thinking about different pit types like truss systems and nice displays, we decided to do a more modular approach. Our theory is that we go to competition to compete at the highest level we can, not to waste time setting up a huge pit display. The faster you can setup your pit, the faster your robot gets inspected and the more practice time you get. Our inspiration for a new pit design came from another team's pit; The Greybots, FRC 973, "Super Pit". The idea of the super pit is to create a mobile work space that is super easy to setup, with a professional look and great organization and functionally. We have used our super pit since the 2018 season, and it has allowed the team to be more productive and organized both in the shop and at competitions. Our super pit has gotten plenty of attention at events and has helped earn several Pit Safety Awards. Our team's unload and setup time has decreased from hours to minutes. It takes around 10-15 minutes to unload from our trailer to full set up in the pit.

Several modifications have been made to our pit that are not yet documented; new tool box, on-board air compressor, stationary battery chargers. |

| 5460 Super Pit Components |

|

|

| ||||||

Special thanks to the following for support with 5460's Super Pit

|

FRC Team 973 for Inspiration & Design

Doug Randlett for Welding Services Platinum Coatings for Powder Coating William E. Walters for Sheet Metal Churches Lumber for Wood |

Taylor Steel for Steel Tubing

Goyette Mechanical for Electrical Supplies Tim Likpa for Wiring and Assembly Paul Schneider for Wiring and Assembly Matthew Schneider for CAD Design |